500kg/H PE PP Bottle Washing Line Friction Washer Machine for Waste Plastic PP PE Pet Film Bag Bottle Flakes Washing Drying Recycling

Basic Info

| Model NO. | PE2 |

| Computerized | Computerized |

| Certification | QS, GMP, ISO9001:2008, CE |

| Input Material | PE PP Bottles |

| Final Product | Small Scraps |

| Final Size | Customized |

| Factory Voltage | 380V 220V 400V 415V Can Customized |

| Motor Power | 18.5/30kw Customized |

| Capacity | 300-2000kg/H |

| Motor Brand | Siemens Beide |

| Invertor | ABB |

| Contactor | Siemens |

| Gear Box | Jc Brand |

| Bearing | Zwz/NSK |

| Weight | 20ton |

| Temperature Controller | Omron Rkc |

| Machine Color | White and Blue, Customized |

| PLC | Siemens |

| Transport Package | Coverd by Plastic Film |

| Specification | 40m*1.8m*2.5m |

| Trademark | Camel |

| Origin | Zhangjiagang, Suzhou, China |

| HS Code | 8477800000 |

| Production Capacity | 100sets Per Year |

Product Description

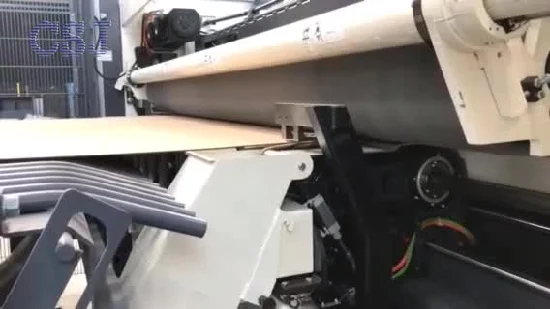

Pe Pp Plastic Film Bottles Washing and Recycling Machine

Flow Chart

Belt Conveyor---Shredder&Crusher---Screw Conveyor---Floating Washer---Screw Conveyor---Hot Washer--- High Speed Friction Washer---Screw Conveyor---Floating Washer---Dewatering Machine---Pipe Drying System---Storage Hopper

More details

Product Parameters

| Model | Capacity/output(kg/h) | Installed power |

| PE-300 | 300-400 | 120 |

| PE-500 | 500-600 | 150 |

| PE-1000 | 800-1200 | 250 |

| PE-2000 | 1500-2000 | 350 |

2. To crush the Pe Pp plastic into small scraps and make it clean.

3. This line is composed of belt conveyor, crusher, cold & hot washing system, dewatering, drying, packing system, etc.

4. Easy to operate, Full automatic.

5. Production capacity: 300KG/H, 500KG/H, 1000KG/H, 1500KG/H, 2000KG/H

Main Advantages:

1. Automotive line for recycling the various kind of Pe Pp plastic,such as film and bottles.

2. The final product is the cleaning flakes, if you want the final product is pellets, we should equip the granulating line again.

Features:

Capacity: 300-2000kg per hour(more higher output can be customized)Moisture of Pe Pp scraps: Less Than 1.5%This line is high automatically

Company Profile

Zhangjiagang Camel Machinery is one of professional manufacturers for plastic extrusion and recycling equipment in China. CAMELMACHINERY aim is to be a top plastic equipment supplier in the world, base on the spirit of this principle, we are not only made our best to meet the market demand but also enhance innovative ability. CAMELMACHINERY offers following major product lines :1.PVC/PE/PPR/PP pipe extrusion line 2. PVC garden hose/spiral hose/steel wire reinforced hose extrusion line 3. WPC extrusion line4.PET bottle recycling line5.PE/PP film recycling line6.UPVC PVC ceiling wall panel extrusion line,7.WPC foam board production line,8.Single shaft shredder,9.Double shaft shredder,10.Plastic crusher and so on...Our Customer

Certifications

Packaging & Shipping

FAQ

Q1:What about the payment?A1:TT,L/C at sight or other. Always 30% down payment as deposit,70% balance pay before shipping.

Q2:If you will send engineer coming to our factory to install and test the machines?

A2:Yes,Every set of machine we will send professional engineer to your factory and help installation and test the machines for you.

Q3:If you have CE,SGS,ISO certificate?

A3:Yes,except these,if you also need other certificates,we also can help to apply.

Q4:If we buy your machines, can you offer us wear-out spare pats?

A4:Yes,We provide our high quality machine 1 years' guarantee,and we will also offer you 1 years wear-out spare parts for free. Once your machines broken or doesn't work within 1 years and you can't solve it, firstly, we will try to help you to find problems from your words description by phone or other communication tools. Secondly, if the phone solutions still not work, our engineers will go to your factory to solve it. Meanwhile, they will teach you the related experiences for fixing.