Shanghai Factory Auto Cable Coils Plastic Film PE Sealer and Shrink Packing Machine with Conveying Line

Package size per unit product 450.00cm * 95.00cm * 195.50cm Gross weight per unit product 1300.000kg GH-6030AC + SF-6040;

Basic Info

| Model NO. | GH-6030AC+SF-6040E |

| Type | Automatic Wrapping Machine |

| Driven Type | Electric |

| Application | Beverage, Defferent Boxes |

| Automatic Grade | Automatic |

| Inclusion Degree | Sleeve Wrapping Machine |

| Structure | Shrink Wrapping Machine |

| Film Frame Structure | Shrink Wrapping Machine |

| Series | Shrink Wrapping Machine |

| Applicable Cable Width | 100-200mm |

| Shrink Film | PE |

| Power Supply | 20kw 220V/380V 50Hz |

| Certificate | ISO, CE |

| Air Temperature | 0-300ºC |

| Heating System | Air-Circulation |

| Blade Length | 350mm |

| Transport Package | Wooden Boxes |

| Specification | 4500× 950× 1955mm |

| Trademark | SURFON/KUKO |

| Origin | Shanghai, China |

| HS Code | 8422303090 |

| Production Capacity | 100 Sets/Month |

Packaging & Delivery

Package size per unit product 450.00cm * 95.00cm * 195.50cm Gross weight per unit product 1300.000kgProduct Description

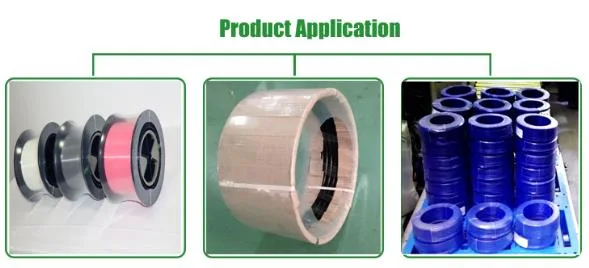

- GH-6030AC + SF-6040E Fully-auto sleeve sealer and shrink tunnel is designed for a single round object. This machine can connect production line to make automatic feeding, wrapping, sealing, shrinking and cooling to achieve unmanned production;

- GH-6030AC introduces internationally advanced technology and production process. The performance is reliable and can automatically calculate the daily output;

- It is a professional sealing and shrink equipment that specifically designed for welding consumables industry. Induction film-feeding greatly reduces the waste of film;

- Original Autonics digital temperature controller with precise temperature can show the temperature status when sealing;

- Mechanical step less speed control device to adjust the speed of the feed conveyor;

- The usage of Siemens PLC and touch screen to achieve the integrations of mechanism, electricity and pneumatic;

- Using a specially designed three-piece sealing knife keeps solid sealing line, no cracking and anti-sticking;

- Feeding conveyor is customized for the wire with straight feeding;

- SF-6040E using imported double air circulation motors so that the hot air in the oven can spread more evenly to get a good shrink effect

- The use of frequency inverter controls transmission speed which has the function of infinitive speed;

- Large amount of cooling air flow, rapidly cooling the product after hot shrinking;

- The shrink packaging equipment is suitable for welding industry with the advantages of anti-moisture, anti-rust and extending the welding consumables storage period.

| Model | GH-6030AC+ SF-6040E |

| Power | 20kw |

| Power Supply | AC380/220V 3 PH 50/60Hz |

| Applicable Cable Width | 100-200mm |

| Applicable Cable Diameter(can be customized) | 300mm |

| Tunnel Chamber Size LxW×H | 1800x600×400mm |

| Blade Length | 350mm |

| Air Temperature | 0-300ºC |

| Table Height | 820±50mm |

| Packing Speed | 0-12m/min. |

| External Air Source | 6-8kg/cm2 |

| Shrink Film | PE |

| Machine Size L×W×H | 4500×950×1955mm |

| Crate Size L×W×H | 4550×1000×2105mm |

| G./N. Weight | 1300/1200kgs |

KUKO Company Introduction

Our Factory

Our Clients

Quality Certificate

Packing Service

FAQ

1. Who is KUKO MACHINERY?

Shanghai Kuko Packing Machinery locates on No.408, Tianjiu Road, Songjiang District, Shanghai, 201603, China, which specializes in manufacturing Hooding Machine & Shrink Wrapping Machine for 18 years.2. What are the terms of payments?We accept L/C,T/T,Western Union,Money Gram etc.

3. How long is your warranty? What does your After-sales Service include?The machine warranty is one year. We provide professional machine solution and machine layout design. We will delivery machine on time after debugging with wooden packages. We offer professional installation, engineer technical support online and spare parts service.4. What's your delivery time? In general,the delivery time is within 15-90 days after payment. We'll make the delivery as soon as possiable with the guaranteed quality.

5. Do you have Mechanical Quality Certification?Yes. We have CE,SGS,ISO 9001:2015 Certificates.6. If it is easy to operate of your machine?Under the condition of ensuring safe transportation, we will not disassemble the machine very much, so that it can be easier to install and debug after you receive our equipment.Meanwhile We already prepare technical manual and operation video to show our customers, then it will be easy to install and use the machine.7. How does your factory do regarding quality control?We have well-trained and professional workers and strict QC system in each production link. And each product has to be 100% inspected before shipment.

You may also like

Send inquiry

Send now