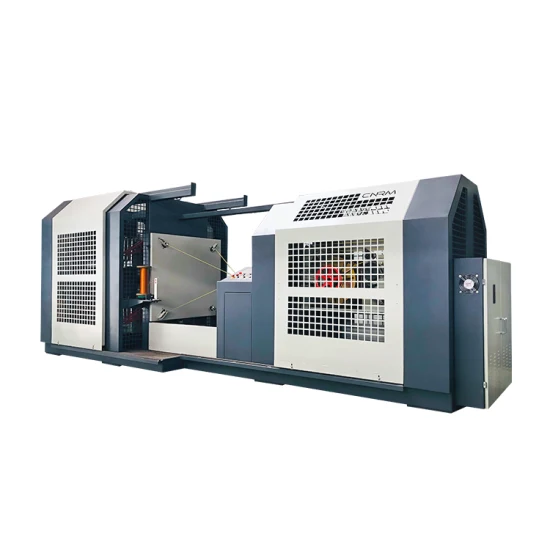

Plastic Swim-Separation Washing Tank (Floating-Sinking) for Cleaning Recycling Line

Basic Info

| Model NO. | RTWWT |

| Plastic Type | PE |

| Screw | Multi-Screw |

| Automation | Automation |

| Computerized | Non-Computerized |

| Certification | ISO9001:2008, CE |

| Capacity | 3000kg/Hr |

| Shaft | 1-4 |

| Customized | Yes |

| Transport Package | by Films |

| Specification | 4500mm-8000mm |

| Trademark | RETECH |

| Origin | China |

| HS Code | 8477800000 |

| Production Capacity | 100 Sets Per Year |

Packaging & Delivery

Package size per unit product 600.00cm * 220.00cm * 200.00cm Gross weight per unit product 2300.000kgProduct Description

Plastic Swim-Separation Washing Tank (Floating-Sinking) for Cleaning Recycling Line

The size of swim tank can be customized.Floating washer mainly consists of washer body, power system, dirty draining system, floating washing system and water circulation system 5 parts.

1. The body bears all the room of processing material, and so there is a high requirement for the tightness of the body. Leakage of water phenomena is now allowed during processing material. The part of body contacted with water is made of stainless steel. The material of both sides of the slot is A3 and the diameter is 10mm.

2. The power system makes the rollers to rotate toward the same direction and by the same principal axis chain, then to make sure the synchronization of all the rollers.

3. The dirty draining system consists of dirty draining screw and motor. The dirty draining screw is at the bottom of the floating washer. The motor drive the screw to rotate and then push dirties out from the dirty draining port.

4. Floating system is consisted of rollers made of stainless steel which has two styles and is used to feed and wash. One style is helix roller which is used to enlarge the material contacting area and to make washing better. The other style with 6 axes is to push material and make the material dip into water enough.

5. There is a water sensor to auto control the height of the water, if the water is over the highest level, the sensor will stop supplying water to prevent water spilling over.

Plastic sinking floating washing machine is used for floating wash and separating the PP,PE,impurity,waste and label. The retarder of the floating washer makes all the rollers run in the same direction to push the whole material, the material is dipping and dispersing during the process. For the PP, PE film, the re is impurity including dirty,sand with it will get down to the bottom of the washer.So that the material will be washed and the impurity will be separated,finally the impurity will be vented by the drain scerw,and the clean material will be transported into next unit.According to the different density of different material,the machine makes the material float and down,then clean them clearly.

This equipment has the function of stable mange,low noise, completely wash, it's a necessary part during the whole process.

1. Number of washing roller:4-6

2. Effective length:5000-8000mm

3. Power of floating washer:(2.2-3)KW*2(100L series or Y100 series)

4. Power of drain outlet : 2.2-3KW(100L1 series)

5. Caliber of drain:200mm

Usually plastic floating tank is used in plastic washing recycling line. Below is one case of our plastic recycling machine line: