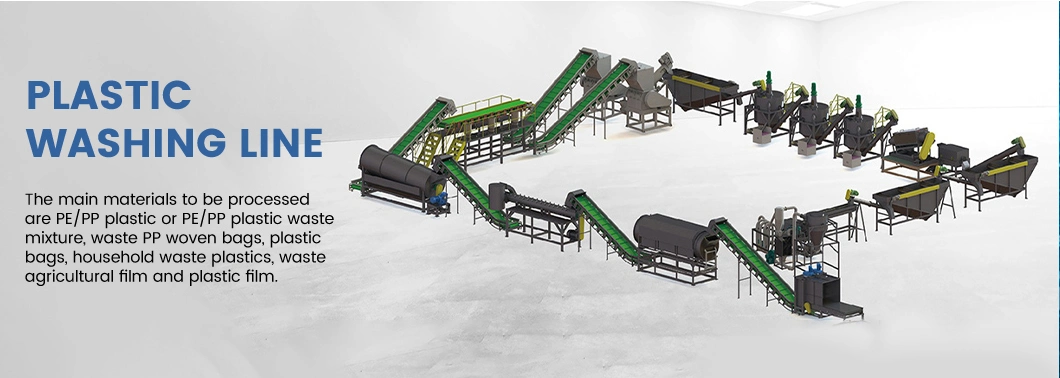

Plastic Sink Float Separate Washing Tank for Pet PP PE HDPE LDPE Plastic Recycling Washing Line

Basic Info

| Product Name | Pet Bottle Recycling Washing Line |

| Machine Type | Pet Bottle Washing Line |

| Voltage | 380 |

| Automatic Grade | Automatic |

| Power (Kw) | 380 |

| Dimension(L*W*H) | According to Model |

| Applicable Industries | Manufacturing Plant |

| Weight | Variable |

| Certifications | CE ISO, ISO CE |

| Moisture Content | <=2% |

| Bulk Density | 0.25-0.35G/M3 |

| Flake Size | <=16mm or Customized |

| Metal Content | <20ppm |

| Label Content | <=30ppm |

| Glue Content | <=30ppm |

| Transport Package | Bubble Film/Stretch Film/Carton Pallet |

| Specification | Customized |

| Trademark | Meetyou Machinery |

| Origin | Jiangsu, China |

| Production Capacity | 50000 Set/Year |

Product Description

Zhangjiagang Meetyou MachineryPlastic Sink Float Separate Washing Tank For Pet Pp Pe Hdpe Ldpe Plastic Recycling Washing LineProduct Description

Retech plastic PET bottle recycling line is the ideal solution for your PET recycling project. Our PET bottle washing recycling line is used to recycle and reprocess waste plastic PET bottles to clean PET flakes including Cola bottles, Pepsi cola bottles, Mineral water bottles, etc. The PET bottle washing line is designed and manufactured by our professional plastic recycling team and can produce the PET bottle plastic washing line between 500kg/h to 5000kg/h models according to customer requirements.The final PET flake's humidity will be less than 1% after processing by our recycling PET bottle washing line, dry and clean flakes could send to our pelletizing machine to make granules directly. Our standard PET bottle recycling washing line consists of a series of plastic recycling machines connected by various types of conveyor systems. The whole sections of the waste PET bottle washing line including a de-baling section, sieving section, label separation section, bottle prewashing section, floatation section, and dewatering section. With rich experience in PET bottle recycling machine design, according to the frequently changing needs of the market, we also support custom PET bottle washing line services. We can design different models of capacity PET bottle recycling lines based on the quality of flakes and the next usage of requirements. The PET bottle washing recycling line can be installed with "I", "L", and "U" shapes according to your workshop. We also help you to design how to install the machines in your factory.PET Bottle Washing Line is working to process post-consumer PET drinking bottles, Cola bottles, etc. By de-baling,trommel screen,label remover,pre-washer-automatic sorting,crusher,floating wash,hot wash,drying,zigzag separator,eddy current separation,color sorting,etc. The washed PET flakes could be food grade or filament grade after our PET bottle washing machine processed them.Our PET recycling line is fully automatic where each piece of recycling machinery is connected via the use of either belt or screw conveyors. In addition, the entire washing line is controlled via a central electric control panel and cabinetOur standard PET bottle washing line is your complete solution for turning dirty bales of PET bottles into clean PET flakes ready for usage in producing polyester staple fiber or further processing into plastic granules via pelletizing. We offer standard washing capacities from 500kg/h up to 3000kg/h and can also manufacture custom wash lines with greater capacities.Our complete PET bottle washing line is an ideal solution for anyone looking to start or improve their plastic bottlerecycling business. This fully automated, turnkey solution processes baled PET bottles into contaminant-free PETflakes. These plastic flakes can be sold for high prices to manufacturers of polyester staple fiber or can be pelletizedinto granules for use in manufacturing other PET products.While our standard PET bottle washing lines are sufficient for most facilities, custom setups with additional machineryand increased capacity can be designed for your specific needs.FeaturesWe devoted ourselves to Plastic crushing washing lines for many years, covering most of Europe and the American market. We are expecting to become your long-term partner in China.It can be made into different lengths according to different requirements. This device is separated by proportion. It can adjust based on different materials, reach the aim of washing, and separate.We are a manufacturer specializing in plastic processing machinery for many years.ApplicationBottles: Bottles include refreshing beverage bottles, mineral water bottles, liquid food bottles, cosmetic bottles, etc; PET bottle recycling: PET bottles are widely used in carbonated beverages such as Coca-Cola, Pepsi, Sprite, etc. Most of them are currently made of PET bottles and HDPE bottles bottom composition, bottle cap material HDPE, a trademark is a biaxially oriented polypropylene (BOPP) film, which is adhered to the bottle body with EVA type adhesive.We devoted ourselves to Plastic washing lines for many years, covering most of Europe and the American market. We are expecting become your long-term partner in China

Specification

| Model | Production Capacity | Installed Power | Production Line Length |

| PE-300 | 300-400 | 70 | 11 |

| PE-500 | 500-600 | 95 | 15 |

| PE-1000 | 800-1200 | 170 | 30 |

| PE-2000 | 1500-2000 | 210 | 37 |

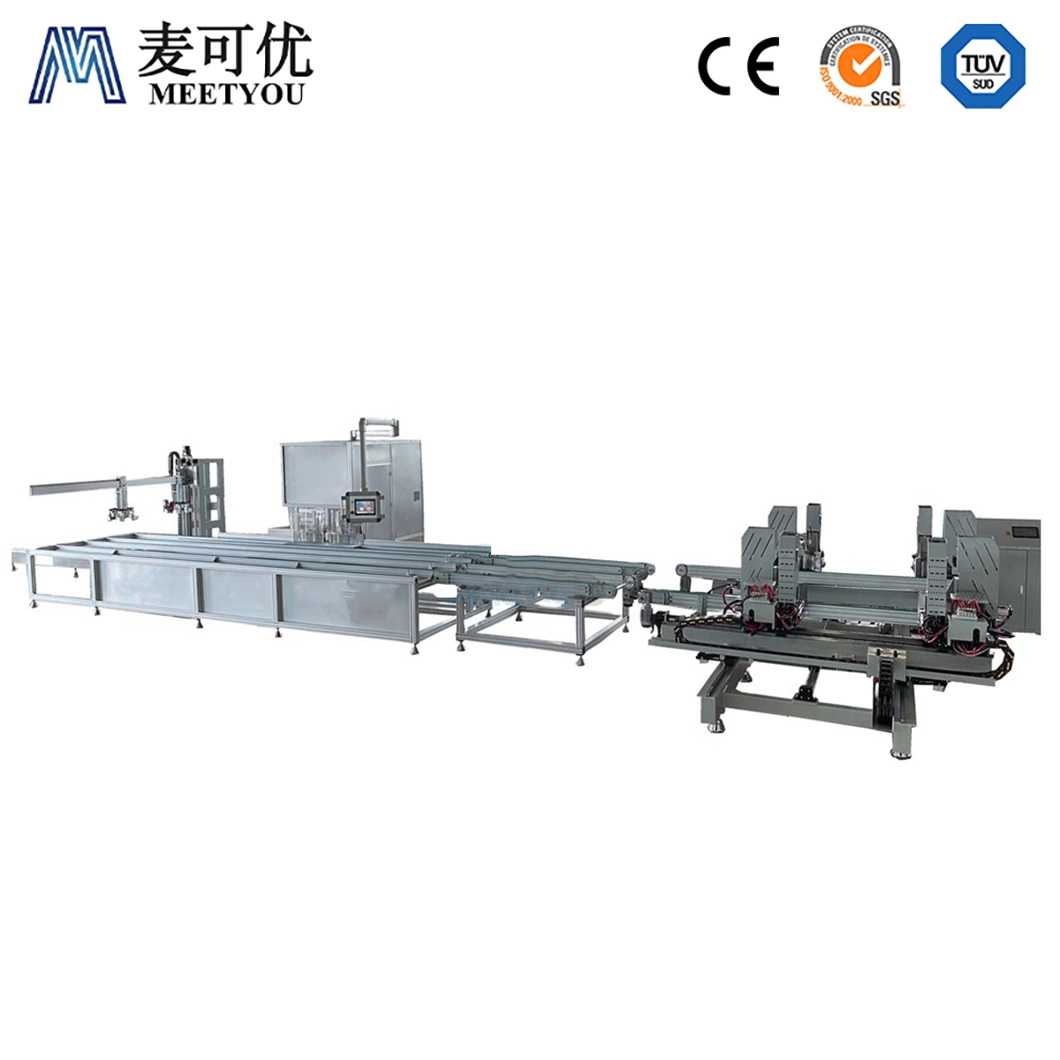

We know the quality is the life of our company. Our company insists to manufacture all machine units by ourselves in order to control the quality strictly by our quality inspectors. To implement this concept, we have built our own tooling and CNC workshop. Even if some parts are from our certified supplier, our quality inspector will check these parts before entering our warehouse.Detailed Photos