Plastic Pet PP PE Recycling Machine Floating Washing Tank

Basic Info

| Model NO. | QX1500 |

| Plastic Type | PE |

| Screw | Single-Screw |

| Automation | Automation |

| Computerized | Computerized |

| Certification | QS, ISO9001:2008, CE |

| Keywords | Pet Bottle Recycling Machine |

| Invertor | ABB |

| Motor | ABB |

| Installing | Engineering Overseas Install |

| Object | Pet Bottle Washing Line |

| Washing Tank | Stainless Steel |

| Transport Package | Nude Package or Wood Case Package |

| Specification | 300-2000KG/HR |

| Trademark | XINTING |

| Origin | China |

| HS Code | 8477800000 |

| Production Capacity | Max 3000kg/Hr One Line |

Packaging & Delivery

Package size per unit product 3000.00cm * 400.00cm * 400.00cm Gross weight per unit product 16000.000kgProduct Description

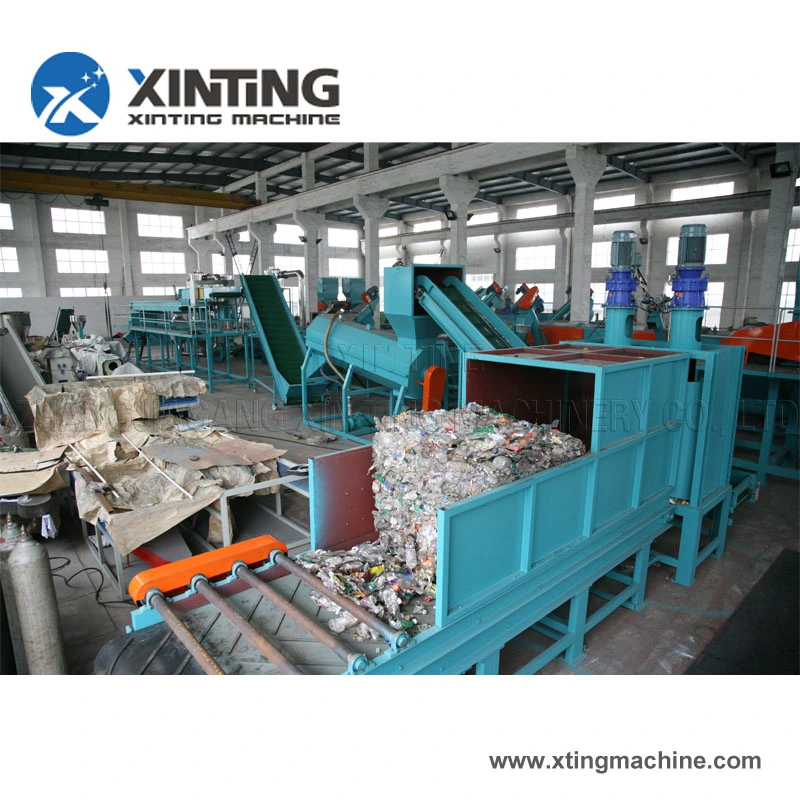

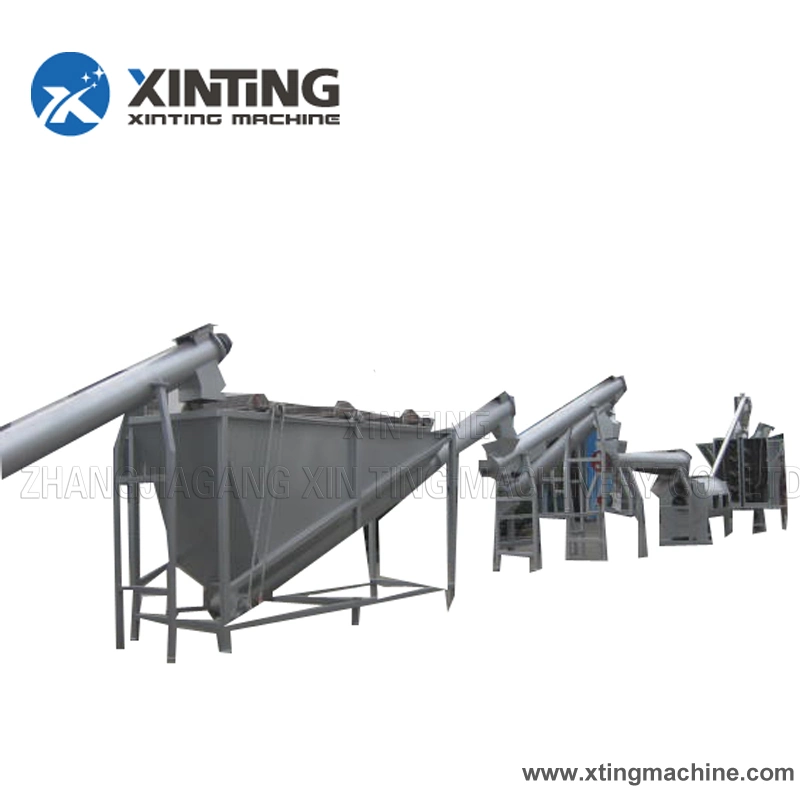

plastic PET PP PE recycling machine floating washing tankThe washing tank include material HDPE bottles LDPE Films PET bottles pp woven bags and so on.

all contact parts we use stainless steel 304 or 316.

Features of pet bottle washing line:

1. High automation level, try best to reduce your cost on labor (especially for three shifts) and ensure high processing capacity: 500-3000kg/hr.

2. Friendly control system (PLC integrated & separated control on each machine) and Touch screen panel, easy for operation, monitor and emergency stop.

3. All parts contacting with plastic material and water are made of high-quality 304 stainless steel; ensure no second pollution to flakes.

4. This China Professional Manufacture PET Bottle Crushing Washing Drying Recycling Line can easily wash and recycle waste PET bottle flakes. Equipment at the end of the washing line so that the completely dry flakes can be collected and packed directly after being washed.

5. The whole production line can be designed on the basis of how dirty the flakes are, and make sure of the quality of the final products.

6. Coordinating the production line with follow programmed work (granulating system), and it will make waste and dirty PET bottles to be the PET granule material and in order to producing new PET bottles.

Flowchart Plastic PET Bottle Washing and Recycling Line for plastic recycling machine :

Conveyor belt →Label remover machine → Sorting table→Conveyor belt → Crusher → Screw loader→ Float washing tank→ Friction washing machine → Screw loader→Hot washer tank → High-speed friction washing machine → Floating washing tank → Dewatering machine → hot air dryer system → zig zag air classifier system → Silo

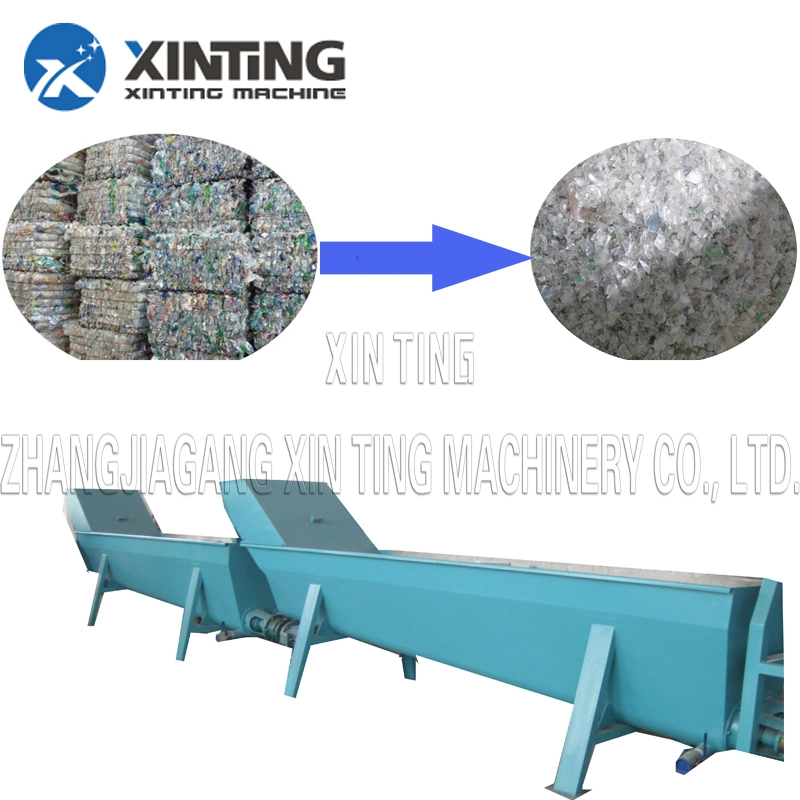

The pet bottle recycling line is specially designed to produce fiber use PET flakes.

The flakes can be used for the 2-D, 3-D PSF, filament yarn, PET strap, PET sheet or PET film.

The pet bottle recycling line can adopt the PLC automatic control of the full line to control the final products quality and save energy.

Pet bottle recycling line can be equipped with the Europe automatic material sorting system and color sorting system.

Pet bottle recycling line can be customized according to the raw material and customer requirement

No. | Machine List | Function |

|---|---|---|

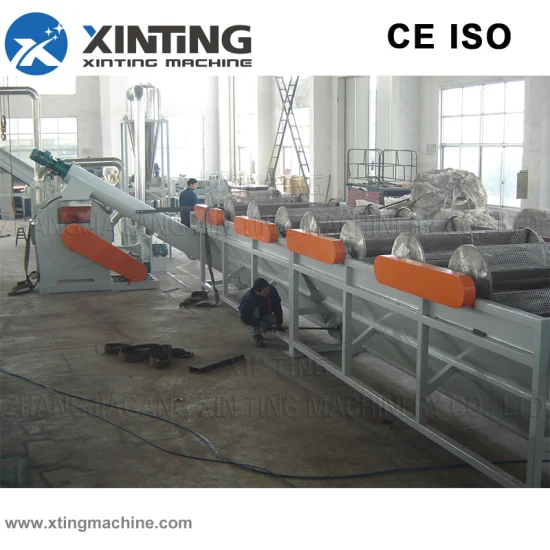

| 1 | Belt Conveyor | Bottles conveying |

| 2 | Bottle Label Remover | Remove above 90% labels for both common and compressed bottle; No flakes waste and no water consumption |

| 3 | Manual Sorting Belt | Manually sort out PVC bottle, labels, and other impurities |

| 4 | Belt Conveyor | Bottle conveyor tp crusher |

| 5 | PSJ1200 Crusher | Bottle crushing into flakes |

| 6 | Horizontal Screw Loader | Conveying flakes to next screw loader |

| 7 | Screw Loader | PET flakes conveying |

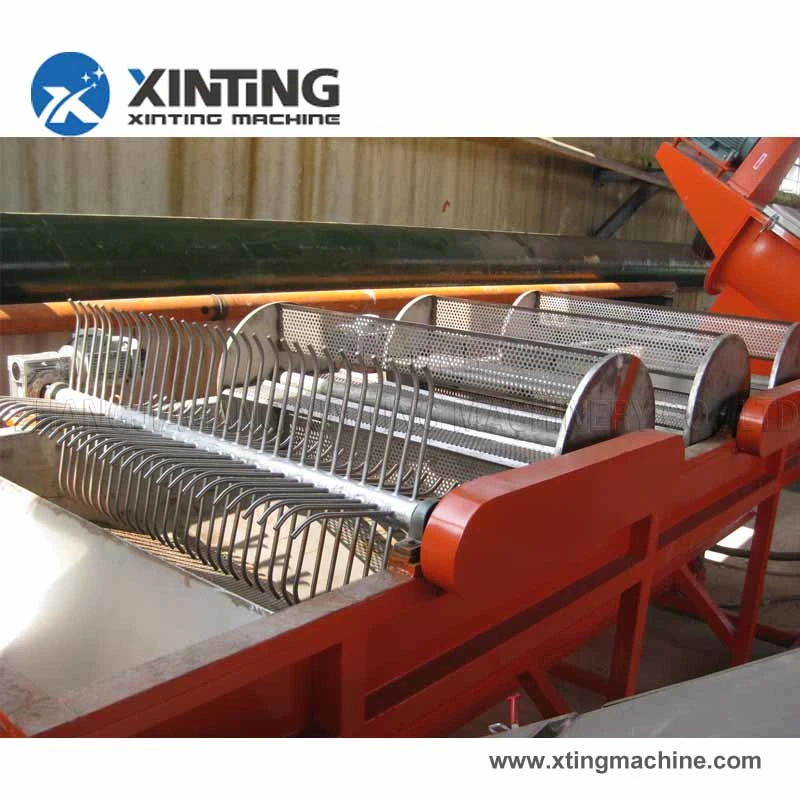

| 8 | Floating Washer | Wash flakes and remove floating materials as PP, PE and Caustic soda |

| 9 | Low Speed Friction Washer | Remove sand, mud and dirty |

| 10 | Hot Washer | After hot washing, it's easier to remove oil, glue |

| 11 | Screw Loader | PET flakes conveying |

| 12 | Hot Washer | After hot washing, it's easier to remove oil, glue |

| 13 | Screw Loader | PET flakes conveying |

| 14 | High Speed Friction Washer | Remove the glue and dirty |

| 15 | Screw Loader | PET flakes conveying |

| 16&17 | Floating Washer | Wash flakes and remove floating material as PP, PE and Caustic Soda |

| 18 | Spray Washer | Remove the Caustic Soda |

| 19 | Centrifugal Dryer | Drying and flakes moisture reach 2% |

| 20 | Pipeline Dryer | Hot air drying, moisture <1% |

| 21 | Label Flake Separator | Remove little amount of label and dust in PET flakes |

| 22 | Packaging System | Storage silo for PET flakes |

| 23 | Electric Cabinet | Electric control for the complete line, can be customized |

| Input capacity | 500kg/h | 1000 kg/h | 2000 kg/h |

| Workshop(M*M*M) | 42 (L)×10(W)×6(H) | 55(L)×15(W)×6(H) | 70(L)×18(W)×6(H) |

| Ancillary staff | 6Persons | 8 Persons | 12 Persons |

| Installation power | 156KW | 307KW | 420KW |

| Water Consumption: | 2Ton/h | 3.5Ton/h | 5 Ton/h |

| Final product | Moisture: max 1%Bulk density: 0.3G/CM3Particle size: 14-18mmMetal content: max.20ppmFloatable contamination: less than 200ppmTotal impurity: 320ppm | Moisture: max 1%Bulk density: 0.3G/CM3Particle size: 14-18mmMetal content: max. 20ppmFloatable contamination: less than 200ppmTotal impurity: 320ppm | Moisture: max 1%Bulk density: 0.3G/CM3Particle size: 14-18mmMetal content: Max. 20ppmFloatable contamination: less than 200ppmTotal impurity: 320ppm

|