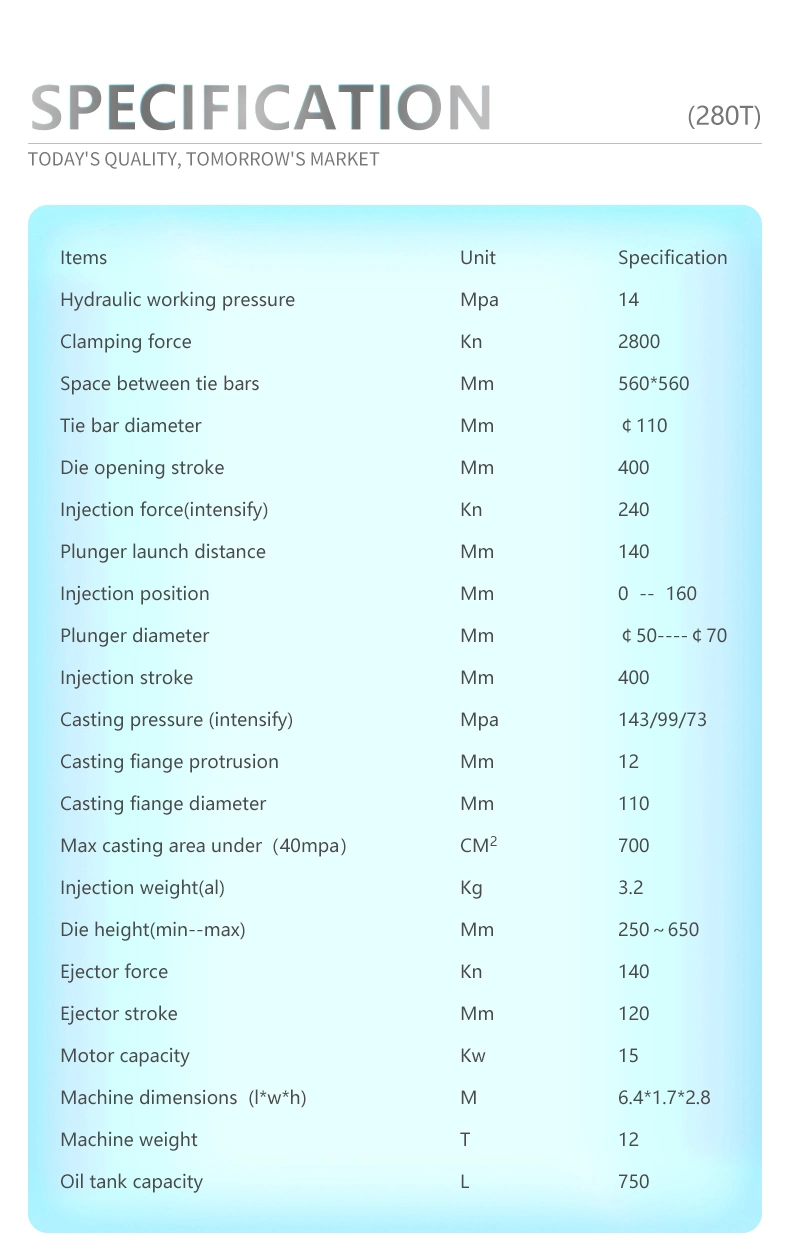

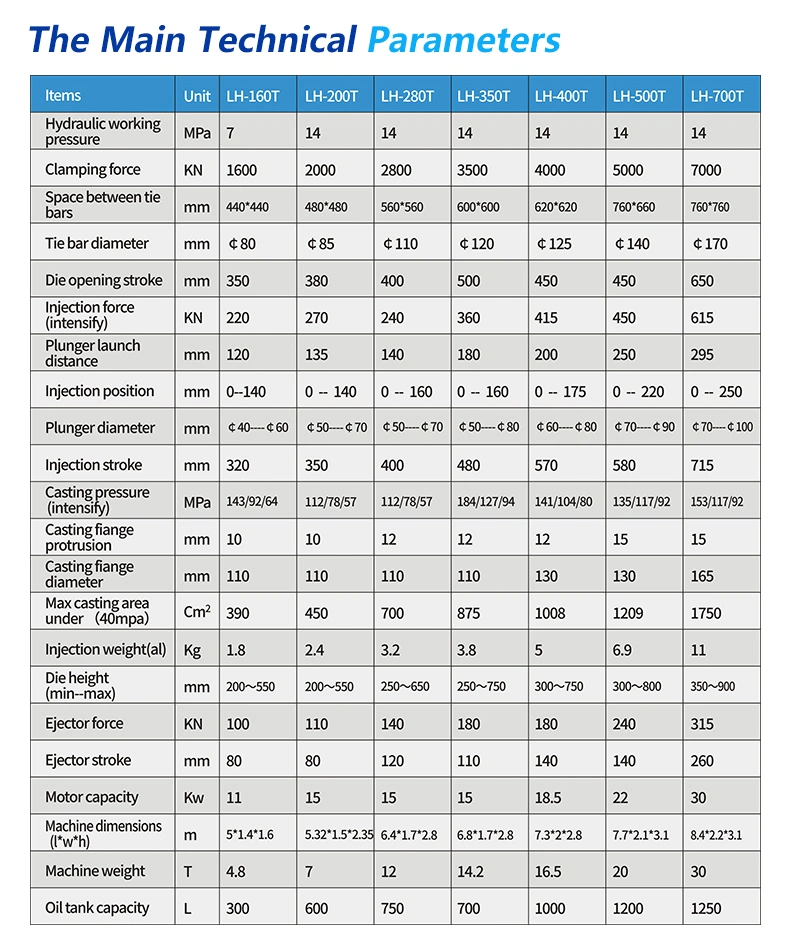

Lh- 280t Cold Chamber Die Casting Machine for Making Aluminium/Brass Alloy and Other Non-Ferrous Metals

Longhua Die-Casting Machine Company,founded in Bengbu,Anhui Province of China in 1982, is a professional high-tech enter;

Basic Info

| Model NO. | LH- 280T |

| Automatic Grade | Automatic |

| Certification | CE, ISO9001 |

| Type | Casting Machine |

| Key Words | Die Casting Machine |

| Die Casting Machine Type | Cold Chamber Die Casing Machine |

| Application | Die Casting Machine Casting Industries |

| Technology | Die Casting Machine Vacuum Technology |

| Usage | Die Casting Machine Surface Cleaning |

| Features | High Efficiency, Energy Saving, High Yield |

| Control System | Computer PLC Control |

| Color | White Door |

| After-Sales Service Provided | Online Support |

| Name | Aluminum Brass Die Casting Machine |

| Foundry Industry | Aluminum/Brass/Zinc |

| Key Words-2 | Die Casting Machine Price |

| Transport Package | Plastic Package |

| Specification | 6.4*1.7*2.8 |

| Trademark | Longhua |

| Origin | Anhui, China(Mainland) |

Product Description

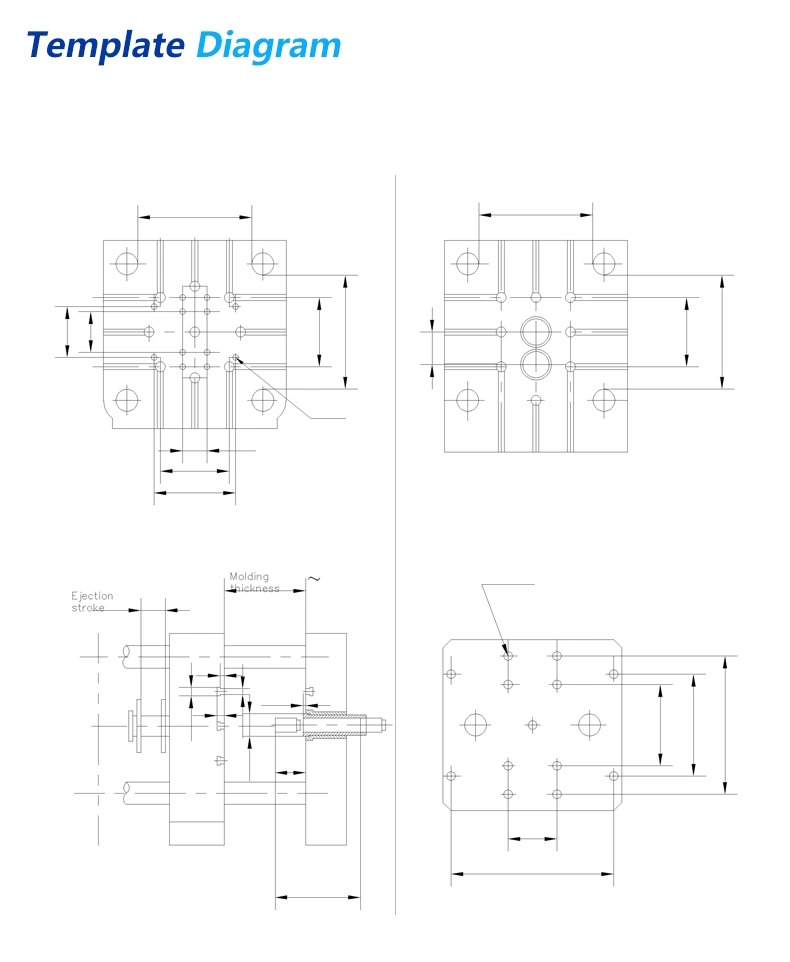

This die casting machine is widely used for mass production of foundry goods made of nonferrous metal such as aluminum, zinc and copper in industries of automobiles, motorcycles, meters and instruments, hardware and supplies.computer-programmed control; hydraulic drive; crank expanding structure;4-rod pilot elastic stress framework; locking that is tensile, faster and reliable; hydraulic boosting and injecting system that is constant and effective; accumulator and injection framework are compose alone; injection rate over 4M/s, and minimum boosting time less than 30ms.

The die casting machine is superior in performance high in productivity and smooth in operation. It is advantageous in technology in China.

You may also like

Send inquiry

Send now