High Quality Waste PP PE LDPE Plastic Film Woven Bags Jumbo Bags Ton Bags Crushing Washing Recycling Line with CE Certificate

Basic Info

| Model NO. | plastic washing machine |

| Computerized | Computerized |

| Certification | ISO9001:2008, CE |

| Material | SUS304 |

| Motor | Siemens |

| Electrical Appliance | Siemens |

| Delivery Time | 30-60 Days |

| National Patents | 20+ |

| Working Experience | 15+ Years |

| Sample Project | Available |

| Exporting Countries | Worldwide |

| Advantages | Less Energy Consumption, Smart Control |

| Final Products Water Content | Less Than 2% |

| Supply Voltage | 3*380V+N+PE; Customized |

| Frequency | 50Hz; Customized |

| Transport Package | Standard Export Package |

| Specification | 500kghr, 1000kghr, 2000kghr, 3000kghr |

| Trademark | POLYTEC |

| Origin | China |

| HS Code | 84778000 |

| Production Capacity | 100 Sets/Year |

Product Description

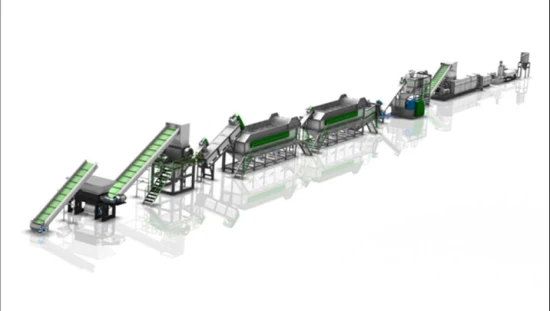

Name: Plastic film agricultural film washing line

Raw materials: Plastic film / agricultural film / greenhouse film / tobacco film / Unweathered LDPE polyethene film (raw materials exposed in the field for more than three years have no actual reuse value)

01 - Features

POLYTEC persistently adheres to the design concept of "SMART RECYCLING, HIGH-VALUE PLASTICS", concentrating on economy, practicality, and stable performance, continuing to seek breakthroughs in equipment production capacity, power consumption, water consumption, finished product loss rate, and degree of automation. In recent years, by actively absorbing Europe's valuable experience in film (PE) and woven bag (PP) recycling, and combined with our company's many years of waste plastic recycling experience, we Manufactured updated PP/PE floating washing line to realize efficient coarse crushing, fine crushing, washing and discharging, dehydration and semi-plasticization.

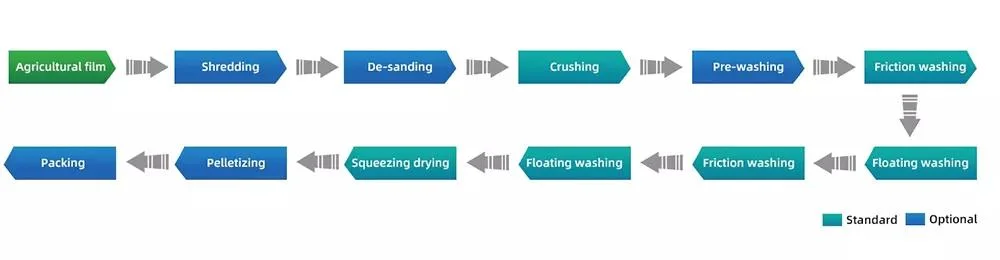

02 - Process flow

This production line mainly recycles agricultural waste film (agricultural film/greenhouse film/tobacco film, etc.). At present, the agricultural waste film is processed in various parts of the country for centralized processing and recycling, and the degree of equipment automation is increased. POLYTEC has been involved in the manufacture of waste agricultural film processing and processing equipment for many years, and the equipment is constantly updated, improved and upgraded and solved many problems in the industry through our technologies. After the waste film is collected, it is pre-processed and cut or shredded so as to turn the large rolls of waste film into small pieces and then put it into the sand removal machine for sand removal treatment. Exorbitant sediment content will shorten the service life of the crusher and affect the cleaning effect. After sand removal, the film enters the crusher for fine crushing treatment. Water is added for crushing, which can play the role of preliminary cleaning. A friction washer is equipped at the bottom of the crusher, which can shake the sediment and dirty water on the material out. The spin-dried film enters the strong friction washer for friction cleaning. This section is filled with water for friction cleaning. Our company specially designs this machine for sand removal and cleaning of mulch film. The cleaning sediment is more than 99%. The cleaned film enters the floating washer and is then dug into the squeezing dryer for dehydration. Subsequent can be connected to a granulating line to make granules.

03 - Photos

| Model | Capacity | Installationpower | Space | compressed air | Average consumption/ton |

| PP500 | 500kg/h | 140-225kw | 200m2 | 0.5m3 | E:67-225kw;W:4-6.5t |

| PP1000 | 1000kg/h | 270-320kw | 400m2 | 0.5m3 |

Certifications