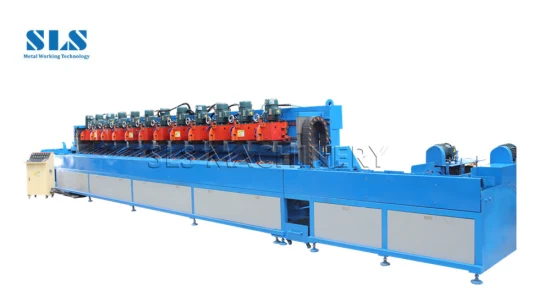

High Efficiency Tube Cold Cutting and Conveying Equipment Pipe Profile Cutting Machine with Autoload

Basic Info

| Model NO. | MC-400CNC-MH |

| Certificate | ISO,CE |

| Cutting Heads | Multi Heads |

| Cutting Type | Wet Cutting |

| Head Driven | Gear+Worm or Full Gear |

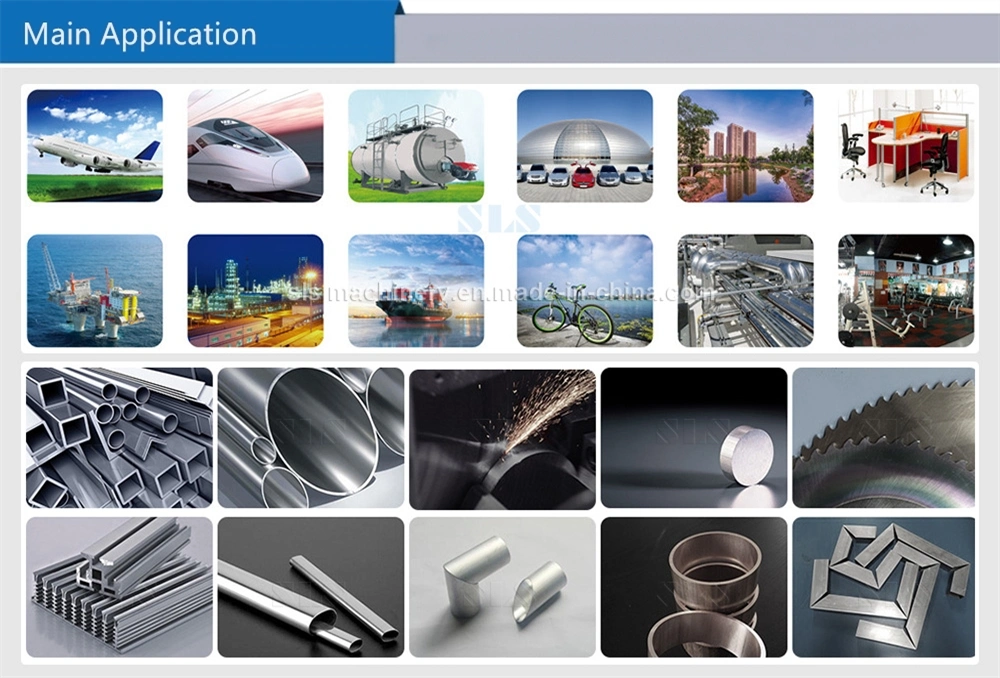

| Applicable Shape | Round,Square,Rectangle,Oval,Profile |

| Applicable Material | Ms.Ss,Copper,Aluminum |

| Voltage | Can Be Customized |

| Color | Standard or Customized |

| Cooling | by Fan or Water |

| Controlling | PLC |

| Advantage | Automatic Magazine Loader |

| Company Type | Manufature |

| Transport Package | FCL |

| Specification | 76mm or Customized Size |

| Trademark | SZ-SLS |

| Origin | China |

| HS Code | 846150 |

| Production Capacity | 500 Pieces/Year |

Product Description

Brief Introduction on pipe profile cutting machine

SLS new multi-heads full automatic pipe cutting machine with bundle magazine loader brings you the latest technology in tubecutting systems.The machine provides a continuous process of extracting the work piece from the magazine loader, fast delivery andaccurate cutting.Theworking process is from Loading, Dividing, Automatic Tube Feeding and Cutting. Tube cutting machine brings timesaving as well as higher output and performance.

Together with Control System,tube cutting line offers precision,versatility and stability, which is the most popular in demand when you wanthigh quality and efficiency equipment for cutting tubes and profiles (square, rectangular, oval, etc.).

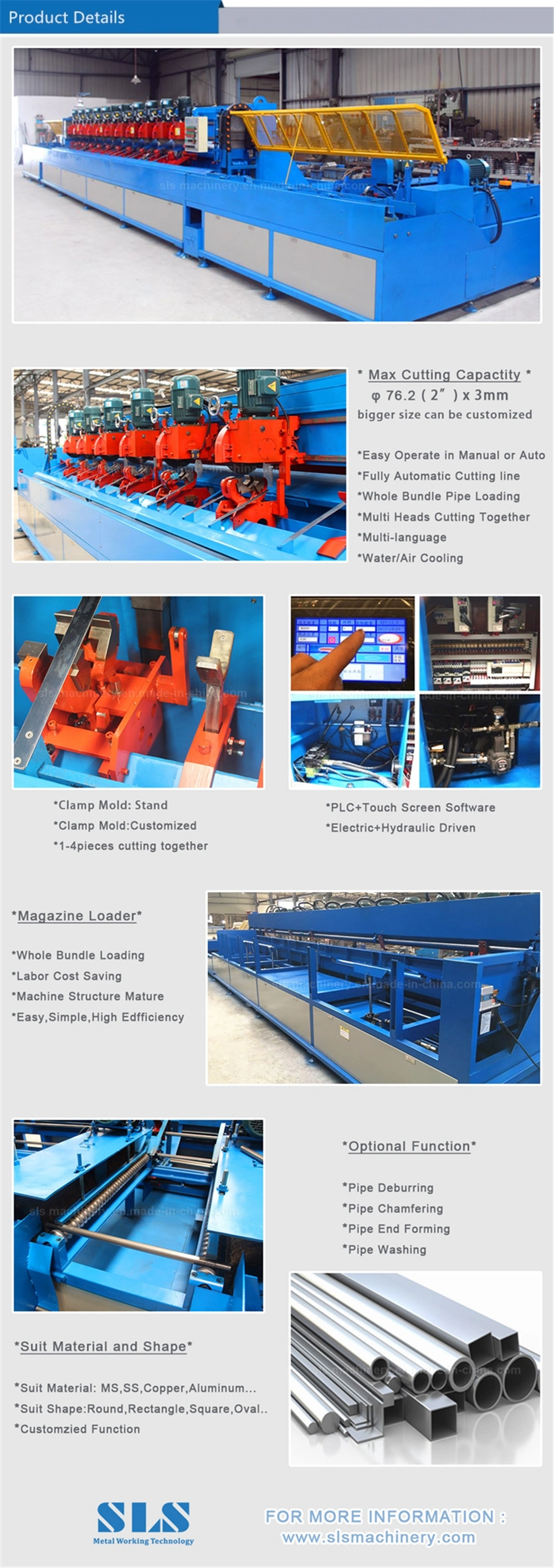

Features on pipe profile cutting machine

STANDARD

Interactive PLC controlling system offers easy access to auto,semi-auto and manual operating modes.

Sturdy frame provides rigidity and lack of vibration during the cutting off the work piece.

Productive circular saw with a level-way stroke.

2 sides and 2 way clamping system: High precision cutting, reduce vibration and soundless while cutting.

Adjustable cutting head position meets various cutting length.

Adjustable cutting head working number meets various cutting length.

Automatic cooling device in the cutting area prolongs the lifetime of outsourcing parts and ensures the stability of mechanical parts.

Automatic lubrication system for all mechanical movement parts prolong the maintenance time and ensures the stability of machine working.

CE, ISO9001 Certification.

Tube Deburring Device

Tube Chamfering Device

Tube Washing Device

Tube End Forming Device

Tube Punching Device

Main Technical Parameters SheetModel MC-400CNC-MH _ Max. Cutting Capacity ¢76×3mm or customized big size _ Cutting Angle 90° or Angle Cutting _ Cutting Heads 11 heads or customized _ Motor Power 2.2Kwx11 _ Controlling PLC(Japan Mitsubishi) _ Suit Cutting Long Tube High Efficiency Cutting _ Clamp Way Front Back/Up Down _ Automation Full Automatic with Auto Loading and Unloading to realize efficiency working _

FAQ:

| 1 Q: Are you a manufacturer or trading company? | A: Yes, we are a manufacturer.We are focusing on metal pipe/tube processing machines production. |

| 2 Q:Where is the nearest airport to your company? | A: Wuxi Airport or Shanghai Airport. |

| 3 Q: How to choose the pipe/tube cutting machines? | A: You have to inform us following details:- Pipe Outdiameter Range- Wall thickness range- The pipe material- Cutting Length- Pipe Original Length- Production Volume- Other requirements |

| 4. Q: Do you have CE certificate? | A: We have CE certificate. |

| 5. Q:How about your service? | A: Before Sales Serive: 1. We will help our customer confirm the right model according to the offered pipe inforamtion.2. Welcome to visit our factory to see our machine and our workshop before you place an order. After Sales Service:1. We provide manual book,detailed machine installation,commissioning video for help you correctly operate machine.2. We provide free installation,commissioning and training at our factory.If you need engineer go to your factory for machine installation, air tickets,food,hotel, local transportation shoule be at your account.3. Any problems on machine,we will reply you by email/tel or other online contact within 24 hours. |