Fluidized Bed Dryer in Food Industry

Principle After heating, the filtered air is distributed into the fluidized bed through the air regulating valve. The we;

Basic Info

| Drying Medium | Air |

| Operational Method | Continuous |

| Type | Continuous Vacuum |

| Origin | China |

Product Description

PrincipleAfter heating, the filtered air is distributed into the fluidized bed through the air regulating valve. The wet material from the quantitative feeder is blown up by the high-pressure hot air to form a boiling state. Due to the extensive contact between hot air and materials, the heat and mass transfer process is enhanced, so the drying can be completed in a short time. The material enters from the feed port at one end of the bed, and flows out automatically or in batches from the discharge port at the other end of the bed after boiling drying for tens of seconds to several hours. This equipment is generally operated under negative pressure.

Features

The processing capacity of the equipment is large, and the emission is also large. The dust is collected through the built-in cloth bag or the external dust collector.

The residence time and temperature of materials in the dryer can be set and adjusted.

The equipment has simple structure, convenient maintenance and even temperature distribution in the bed.

The equipment can be operated continuously, semi continuously or intermittently.

It is applicable to the drying of powder materials with good fluidity. Materials with high moisture content and cohesiveness should be pretreated before drying.

The bed hole structure can be adjusted according to the material requirements, and the material layer thickness can be adjusted through the overflow plate.

Cooling section can be set on the bed surface at the discharge end to facilitate packaging after direct cooling.

Application

Drying of pharmaceuticals, chemical raw materials and food. The applicable material is generally 0.1-6mm, and the best Li crystal is 0.5-3mm.

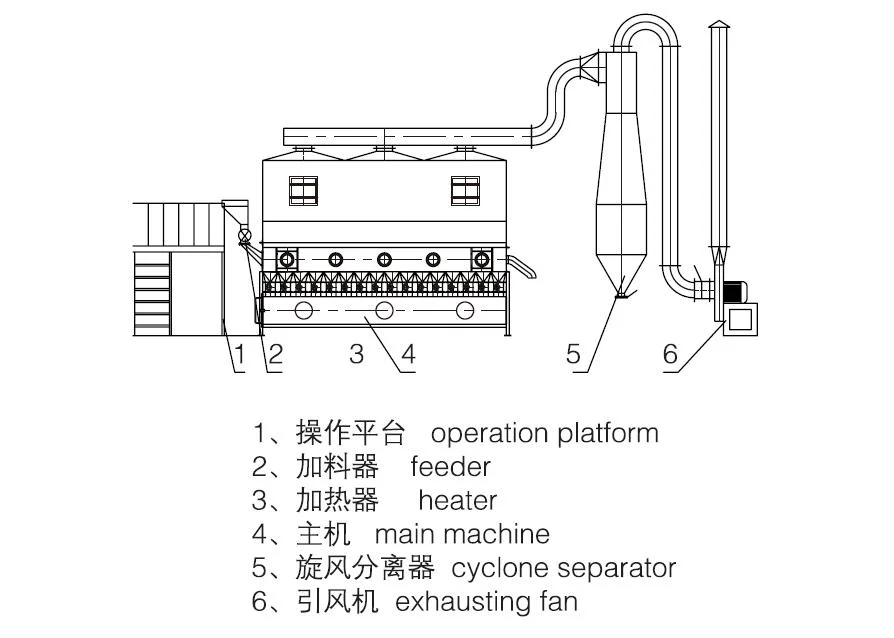

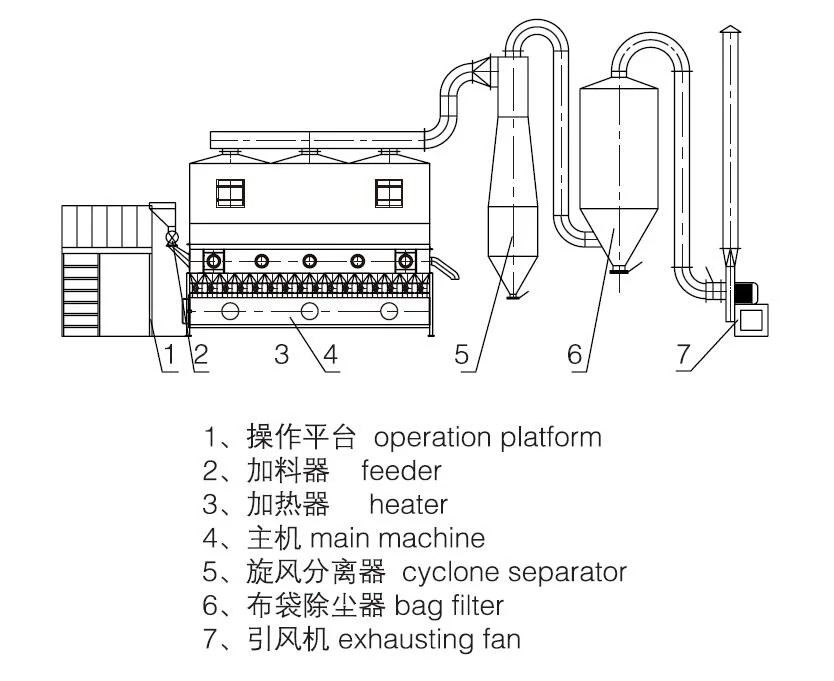

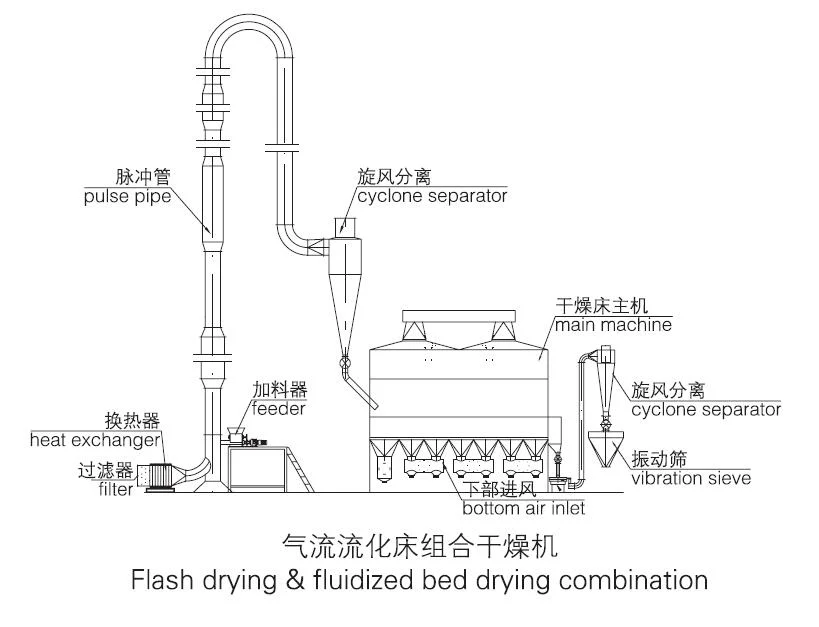

Structure Diagram

Techinical Specification

| Model | Capacity(kg/) | Power of Fan(kw) | Temperature of Inlet Air(ºC) | Feeding Methed |

| XF10 | 10-15 | 7.5 | 60-200 | 1.Feeding methed isdetermined separtely. |

| XF20 | 20-25 | 11 | 60-200 | |

| XF30 | 30-40 | 18.5 | 60-200 | |

| XF50 | 50-80 | 30 | 60-200 | |

| XF1×6 | ~200 | 60 | 150 | |

| XF2×12 | ~1200 | 230 | 150 |

You may also like

Send inquiry

Send now