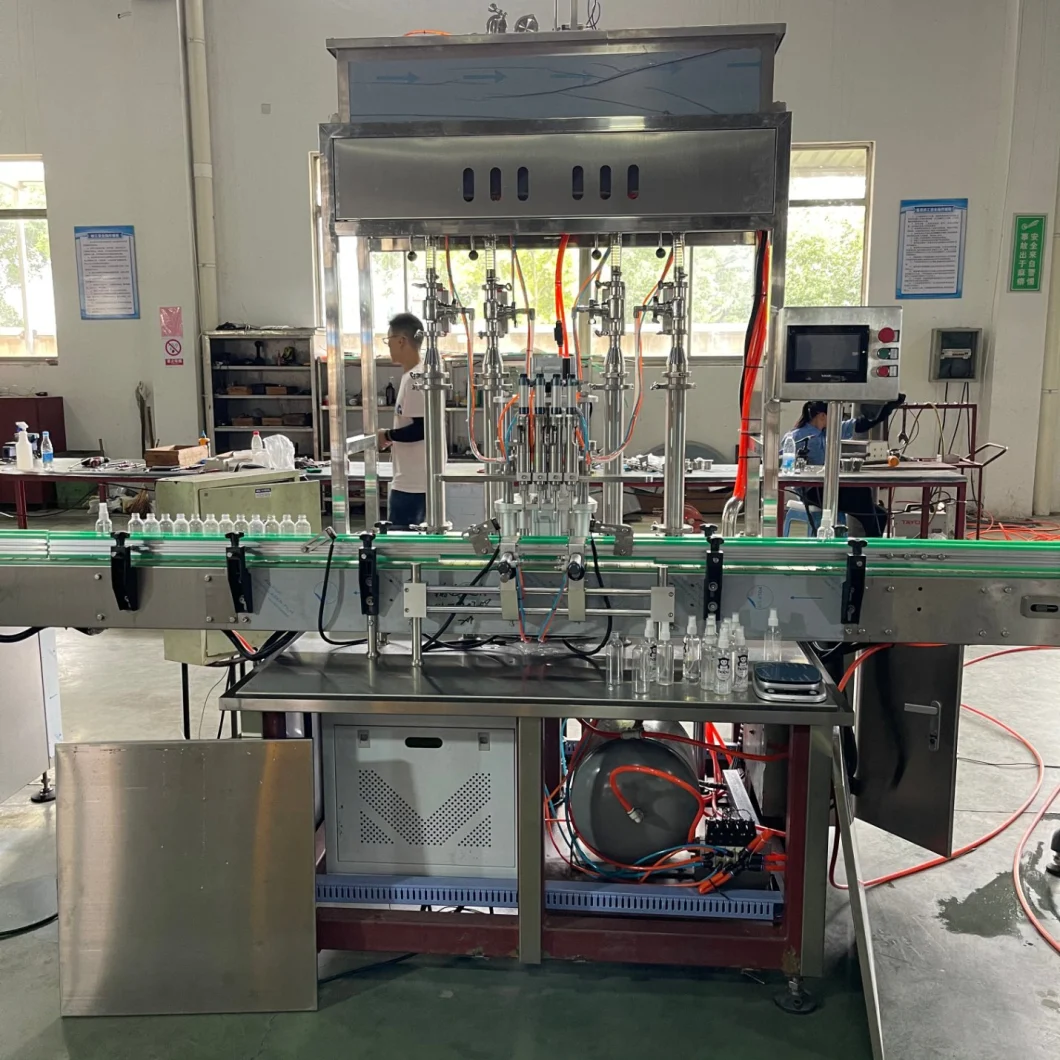

Automatic Alcohol Sanitizer Hand Washing Gel Cleaner Antiseptic Disinfectant Liquid Plastic Bottle Filling Capping Labeling Production Line

Product Description this filling production line for hand washing gel, household disinfectant, shower gel, shampoo, drip;

Basic Info

| Model NO. | Y-GGF |

| After-sales Service | Provide After Sales |

| Warranty | 1 Year |

| Type | Piston Filling Machine |

| Automatic Grade | Automatic |

| Material Type | Liquid |

| Filling Valve Head | Multi-Head |

| Feed Cylinder Structure | Single-Room Feeding |

| Dosing Device | Plunger |

| Filling Principle | Pressure |

| Packaging Container Lifting Structure | Pneumatic Lifting |

| Structure | Linear |

| Packaging | Bottle |

| Packaging Material | Plastic |

| Certificate | SGS, CE |

| Condition | New |

| Transport Package | Seaworthy Export Wooden Case |

| Specification | 1800*1600*1900mm |

| Trademark | GangHong |

| Origin | Jiangsu Province, China |

| HS Code | 8422301090 |

| Production Capacity | 5000sets/Year |

Product Description

Product Descriptionthis filling production line for hand washing gel, household disinfectant, shower gel, shampoo, dripping, liquid detergent and other viscous products filling, adopt the piston pressurized filling method, can be used in a variety of bottle type and cap type, and the bottle replacement time is short, save time and machine costs for customers.

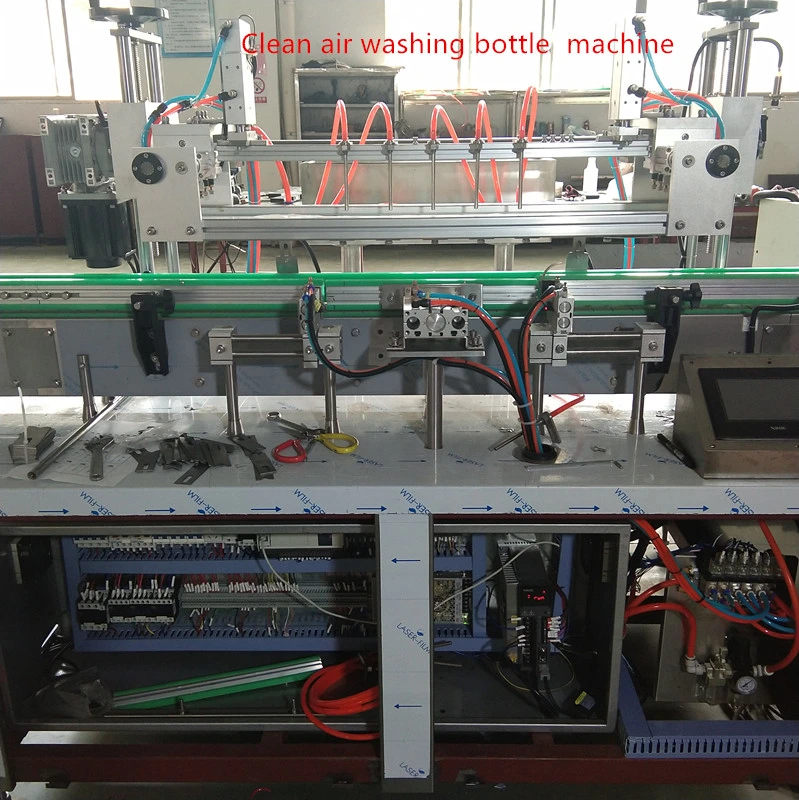

It has realized the full-automatic production process of bottle unscramble, bottle washing, filling, capping, labeling, product collection and packing. The production capacity ranges from 2000 bottles per hour to 8000 bottles per hour. Each machine in the filling production line is exquisitely carved, and the materials in contact with materials are all high-quality 304 stainless steel, which meets the requirements of GMP specifications and provides services from design, production to after-sales, provide customize personalized packaging solutions for customers.

Main performance parameters

| TYPE | CAPACITY | NUMBER OF FILLING HEADS | APPLICABLE BOTTLE TYPE | MEASUREMENT ERROR | MONITOR RATE | POWER | AIR SOURCE | PACKING SPECIFICATION |

| R-HHG4 | 2000 | 4 | PLASTIC BOTTLE,GLASS BOTTLE | +-2G | 3.5KW | 380V,50/60HZ | 0.55MPA~0.65MPA | DIAMATER:50MM~1500MM |

| R-HHG6 | 3000 | 6 | +-2G | 4.5KW | ||||

| R-HHG8 | 4000 | 8 | +-2G | 6.5KW |

Jiangyin Ganghong Packaging Machinery. is a professional engaged in beverage packaging machinery and all kinds of water treatment equipment manufacturers, the company set production practice experience for many years, and absorb advanced technology at home and abroad, improve their own products.The current production is: 0.5t-100T/H complete water treatment equipment, 2000-25000 bottle/hour mineral water, pure water, gas and beverage sets, packaging molding production line;100-2000 barrels of five-gallon barrel assembly line;2000-25000 bottle/hour vinegar, soy sauce, alcohol filling production line;Production line of juice, fruit tea, vegetable protein beverage.At present, we have install our production in more than 30 countries and regions in the world. ZPACK would like to move forward together with you and will spare no efforts. Welcome to our company!

Working scene

Applicable bottles

Our service

Pre-Sales Service

1). We can send you the video of mechanical operation.2). Welcome to our company, we can show you the equipment in our factory. If you come to China and don't know the location of our company, you can contact us to pick you up.3). We can design the machines according your requirements.(material ,power,filling type,the kinds of the bottles,and so on)

After-Sales Service

1). When you finish the preparation conditions ,our engineer will go to your factory to install the machine ,and give you the operating manual ,and train your employee until they can operate the machine well. 2). We provide one year warranty with spare parts free.Packaging&deliveryOur customers

FAQ

1.

Q: Could you provide complete beverage production line?

A: Yes, we can provide RO water treatment equipment, bottle blow molding machine, drink washing, filling,capping equipment, inkjet printer, sleeve labeling machine, automatic shrink packaging machine and etc.

2.

Q: Can you provide oversea installation service?

A: Yes, oversea installation service is available, We have professional installation teams, and have full experience of oversea installation.

3.

Q: Where is your factory? How can i visit there?

A: Our factory is located in jiangyin City, Jiangsu Province, China. It is very near to Shanghai. If you fly to Shanghai, we will pick you up to visit our factory.

4.

Q: How long is the warranty of your equipment?

A: 1 year warranty after receipt check upon delivery, And we will comprehensively provide you all kinds of technical support services in after-sale.

You may also like

Send inquiry

Send now